Saudi Arabia Telecom Industry

The telecom industry in Saudi Arabia is one of the fastest growing industries in the country and is playing an increasingly important role in driving economic growth and development. With the increasing demand for high-speed internet connectivity, fiber optic cabling installation has become a critical component of the telecom industry in Saudi Arabia. In order to meet this demand, fiber optic cable blowing machines have become an increasingly popular tool for telecom contractors and professionals.

Saudi Arabia Telecom Industry

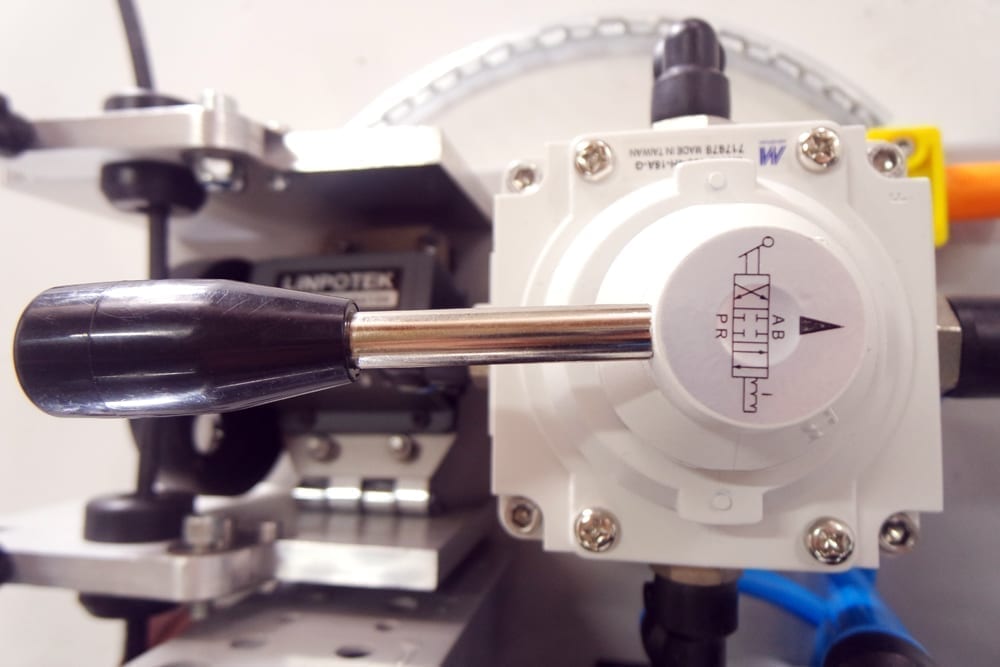

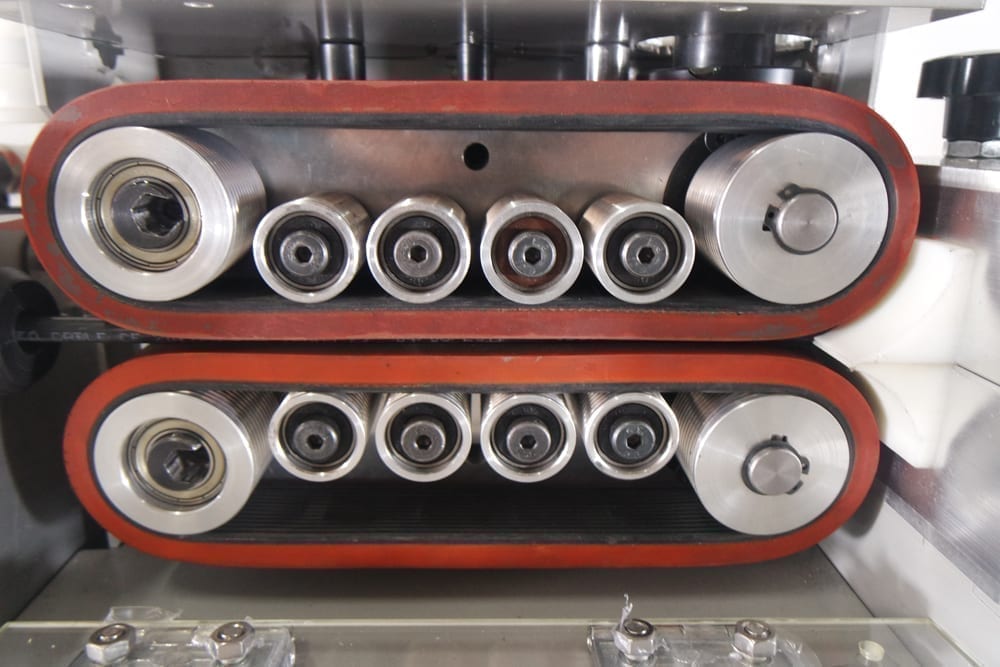

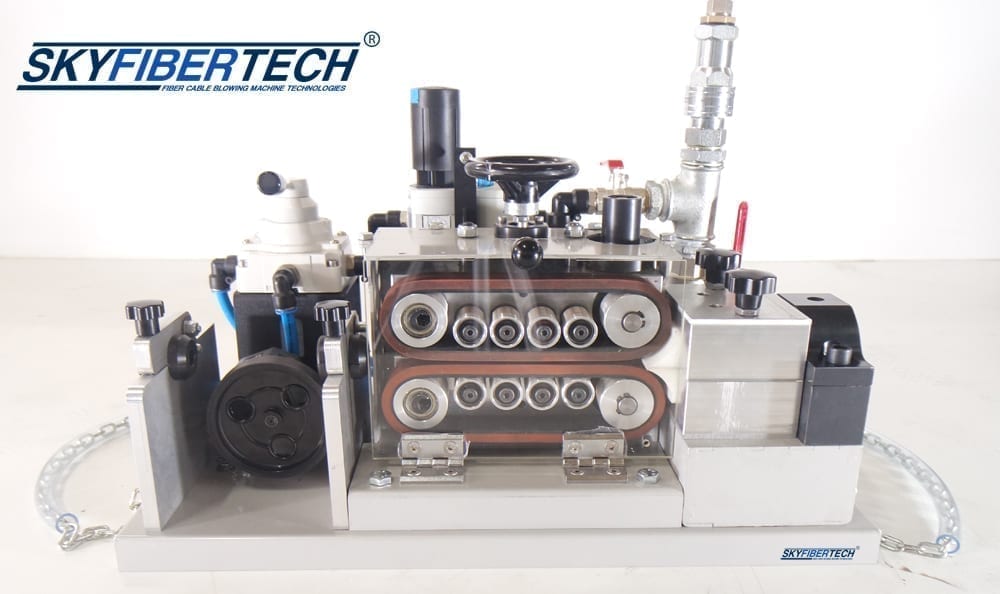

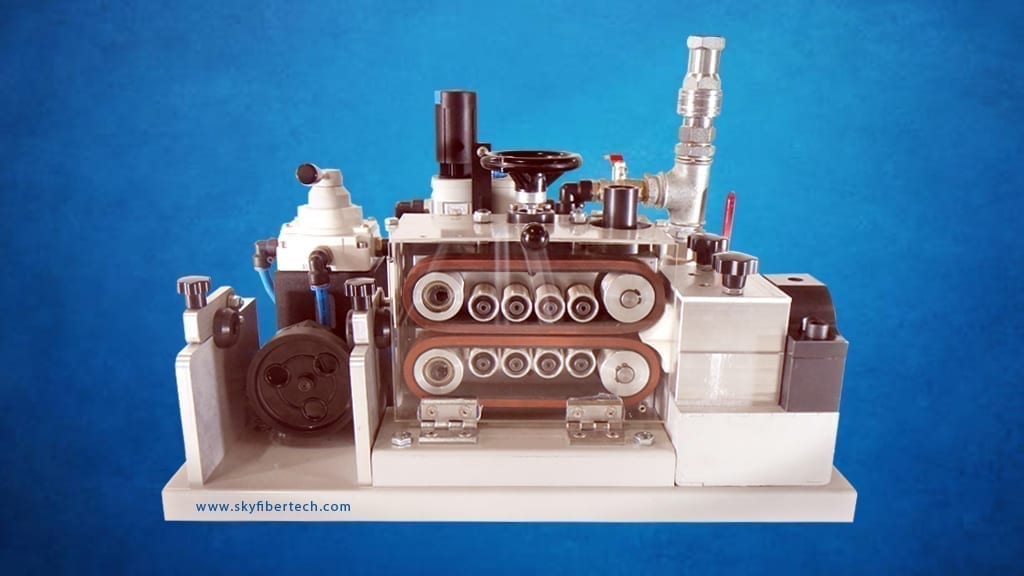

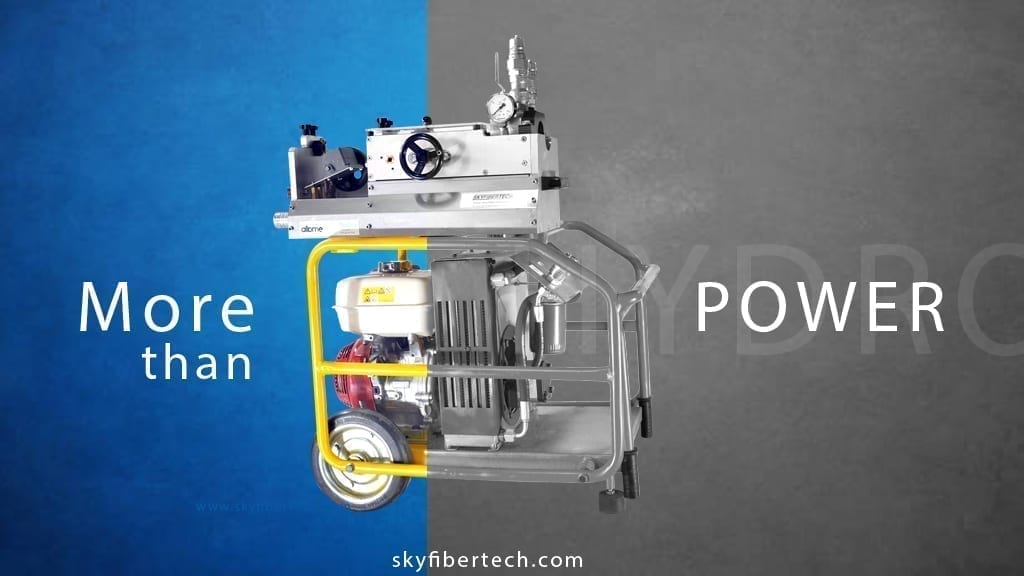

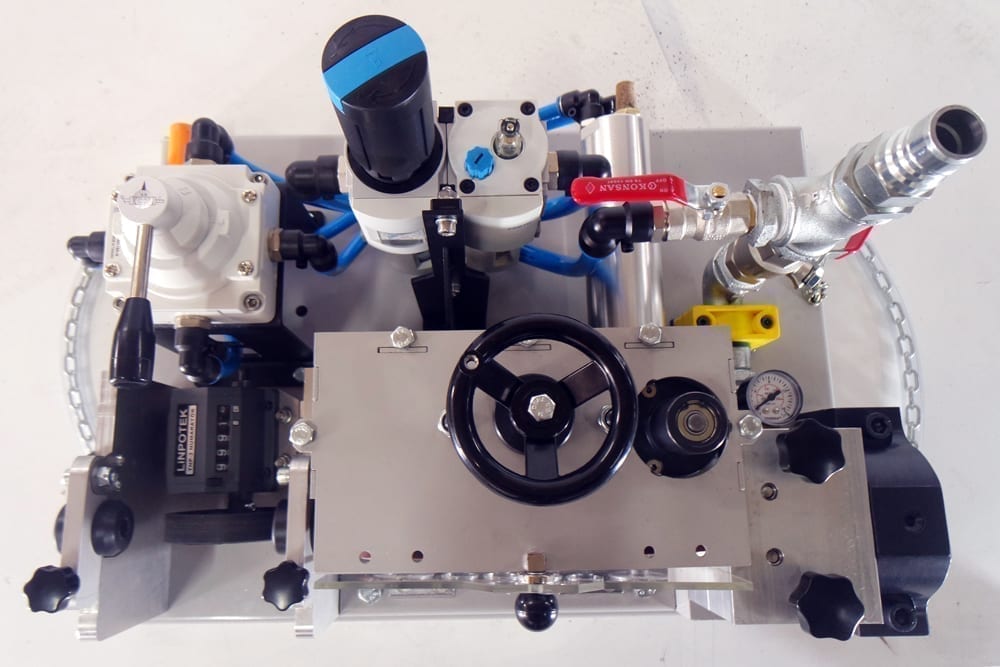

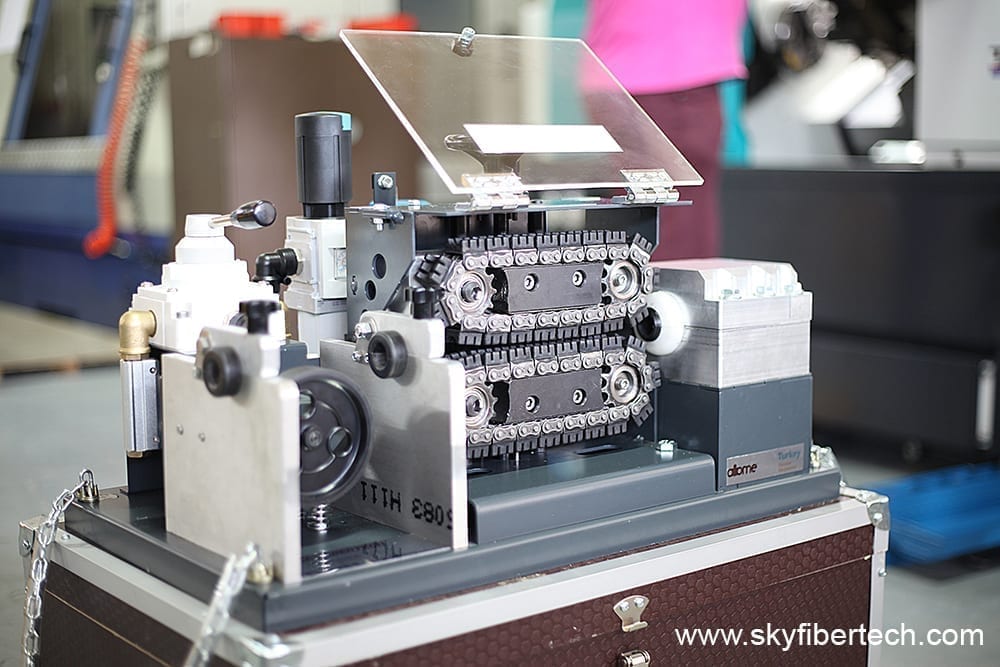

Fiber optic cable blowing machines are specialized machines used to install fiber optic cables into pipes, ducts, and underground conduit systems. These machines use air pressure to push the fiber optic cables through the conduit systems, allowing for faster and more efficient installations. The cable diameter, pipe diameter, air pressure, and duct installation capabilities are all important factors to consider when choosing a fiber optic cable blowing machine.

One of the biggest advantages of fiber optic cable blowing machines is their ability to install fiber optic cables into existing underground pipes, eliminating the need for trenching and reducing the impact on the environment and local communities. This is particularly important in densely populated areas where trenching can be disruptive and time-consuming.

Telecom Industry in SA

In Saudi Arabia, the demand for fiber optic cabling installation has been driven by the growing demand for high-speed internet connectivity, both for homes and businesses. With the increasing use of technology and the internet in all aspects of daily life, the need for fast and reliable internet connectivity has become more important than ever.

The Saudi Arabian government has been actively promoting the expansion of the telecom industry, including fiber optic cabling installation, as part of its Vision 2030 plan to drive economic growth and development. The government has also been working to streamline the regulatory process for telecom projects, making it easier for contractors and professionals to get the necessary permits and approvals for fiber optic cabling installation projects.

The UAE has also been investing heavily in the expansion of its telecom industry, including fiber optic cabling installation. The government has been working to increase the availability of high-speed internet connectivity to all residents and businesses, as part of its efforts to promote economic growth and development.

In conclusion, the telecom industry in Saudi Arabia and the UAE is playing an increasingly important role in driving economic growth and development in the region. Fiber optic cabling installation, with the help of fiber optic cable blowing machines, is a critical component of the telecom industry, allowing for the delivery of high-speed internet connectivity to homes and businesses. The demand for fiber optic cabling installation is expected to continue to grow in the coming years, driven by the increasing use of technology and the internet in daily life.