Cable Blowing Machines Manufacturers

Fiber optic cable blowing machines manufacturers

The end result or the cables that are usedin telecommunication, wiring, and electricity are not how they are actually produced. The cable has to go through a lot of process to be able to reach a stage where it can prove to be beneficial. The cables are installed with a fiber for them to be able to carry on waves that transmits the needed energy. This is done with the help of fiber optic cable blowing machine. The cables are of high use and they are created according to various final purposes they will be fulfilled.

The use of fiber cables hasincreased many folds and in the late 21 century the way to create the optical fiber cable is with the cable blowing machine. The process has gained importance over the years because of the end results it provides. There are many users who still opt for old technique but are left behind in the long race.

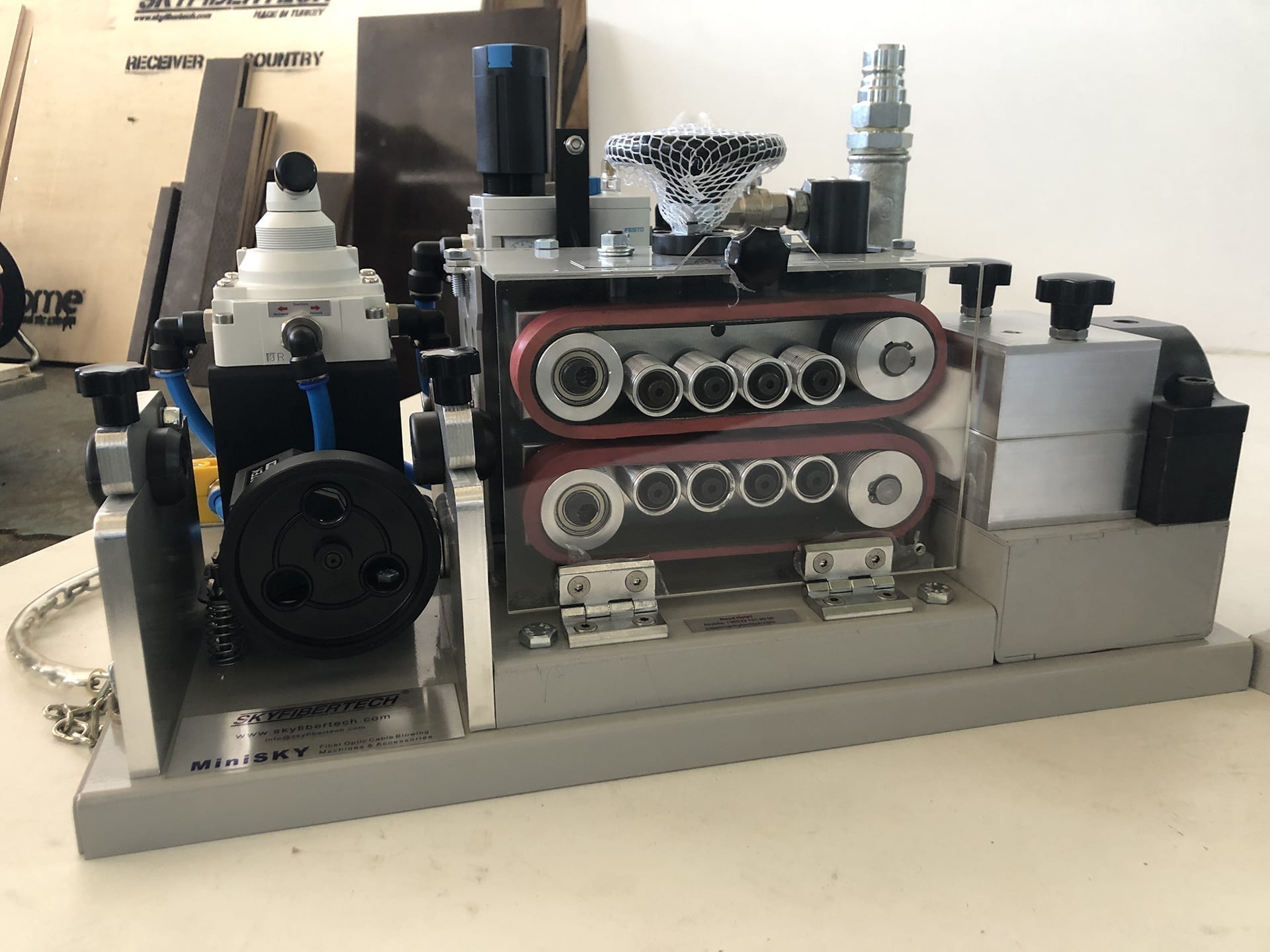

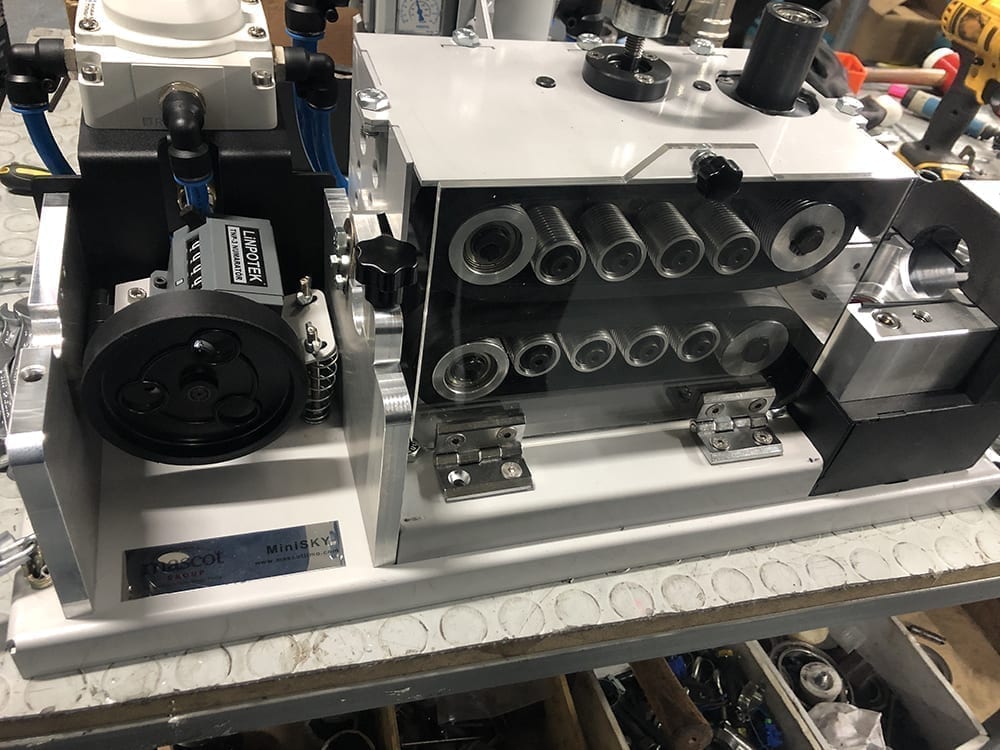

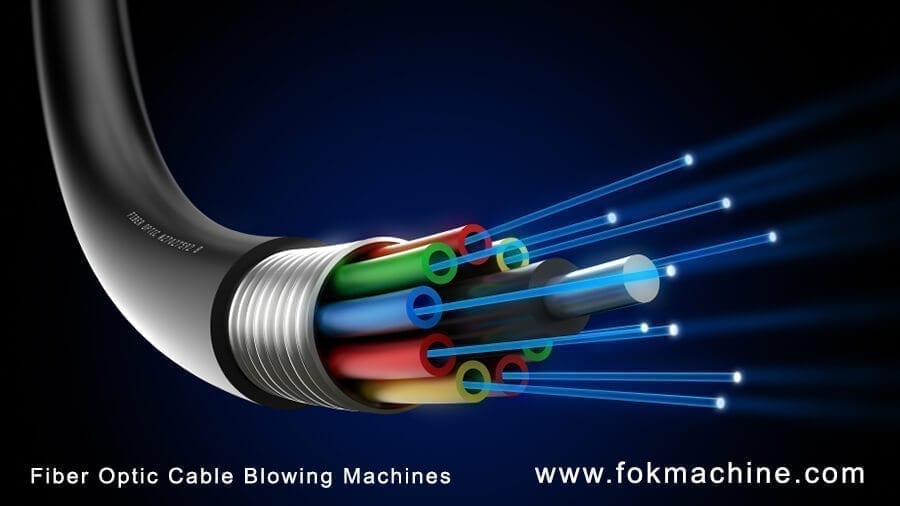

The fiber optic cable blowing machines manufacturers is the newest and the in technology. They provide the cable durability and strength along with providing them the suitable features and properties. The final use of the cable determines the diameter, the strength and the length that is needed for it. The machines are thus designed to provide for all such needs without having to compromise on quality and outcome. Most of the machines are adjustable and they all work on the same process which uses the compressed air to push the fiber optic inside the cable. The technology is great and used for various purposes, adding to its versatility. Cable Blowing Machines Manufacturers.

What are optical fiber blowing machines manufacturers?

The telecommunication sector, the electrical wiring has grown the network since ages. The whole business is based on the effectiveness of the wires used. The wires as they are used in the final process are not what they look like when they are manufactured. Each process or final use calls for a changed fire and installation which is made possible with the help of the fiber optic cable blowing machine manufacturers. These machines are known to be the life providing or rather the functionality providing element to the cables. Cable Blowing Machines Manufacturers.

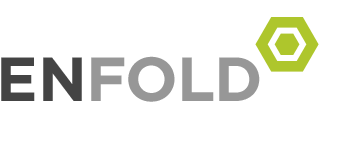

HydroSKY with Power unit 02

The fibre optic cable installation process has been made easy with the help of the new and improved technology. The 21st century has seen the use of these cables with the new installation ways. The fiber optic cables are pushed through the cables with the help of compressed air and machines developed specially for this purpose. Cable Blowing Machines Manufacturers.

Cable Blowing Machines Manufacturers

The fiber optic cable blowing machine manufacturers is available in abundance, fusion splicer, OTDR and others are available for various needs. The user’s needs specific cable for minute detailed uses, here the installation and creation is done in a way to help the users with the same. The machines are available for other cables that have a diameter above 10mm or micro machines that have a diameter below 10mm. The reason for different cables is in the final use as one see that the telecommunication sector is seen using high and thick density cables whereas other sectors for their use make the micro wires used in large numbers.