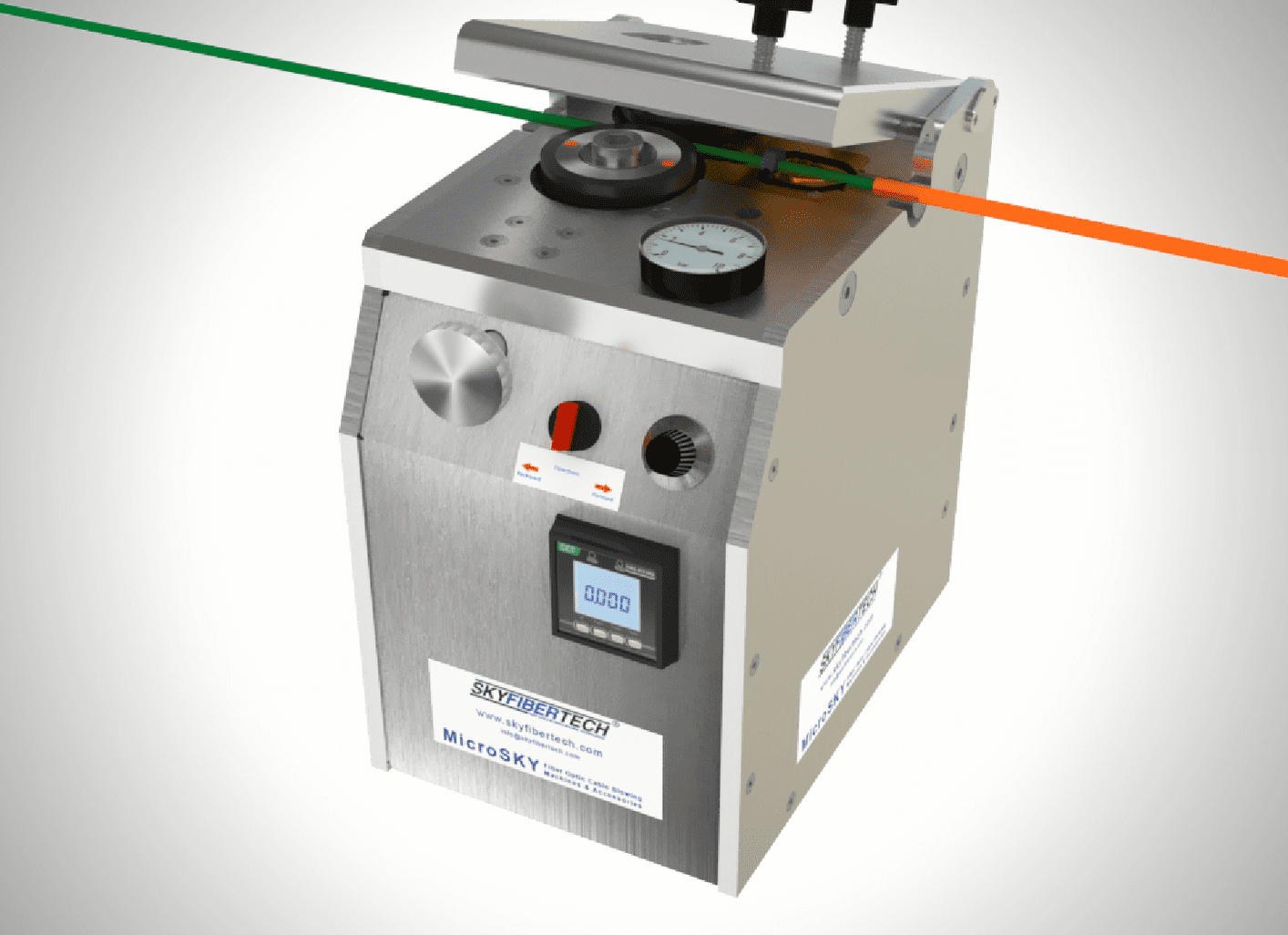

Microduct fiber blowing machines

Microduct fiber blowing machines

Whether it’s a small building or wide area where the fiber optic cable connection has to be installed it needs special care and attention. The reason why fiber optics is handled very carefully is the different formation of cable and the unique technology based on what the cable works. According to the modern science this is the most efficient cable that’s ever been used to transfer data at light speed. The speed of data transfer depends on the fiber quality and material used and also on other factors. ANSI and other organization also give strict direction which every agency has to follow while manufacturing and installing fiber optic cables via microduct fiber blowing machines.

There are many small tools and machines are used to establish the connection under the surface. The pulling rate of fiber cable through the duct should be 3 feet per second in case of rope. There are many other safety measures applied in the fiber optics installation process as the cable is quite expensive and once it get damaged the whole install process have to be altered. The UV radiation and other safety precaution needed to take while making an installation.

The inspection process of live fiber is very important and dangerous too. It needs special glasses to wear by the technician to prevent retina damage. Inspection of both the end should be done by Microduct fiber blowing machines not manually to avoid risk. The machines like microduct fiber blowing machines, battery etc are the main machines and tools which are used to establish a fiber optic cable connection.

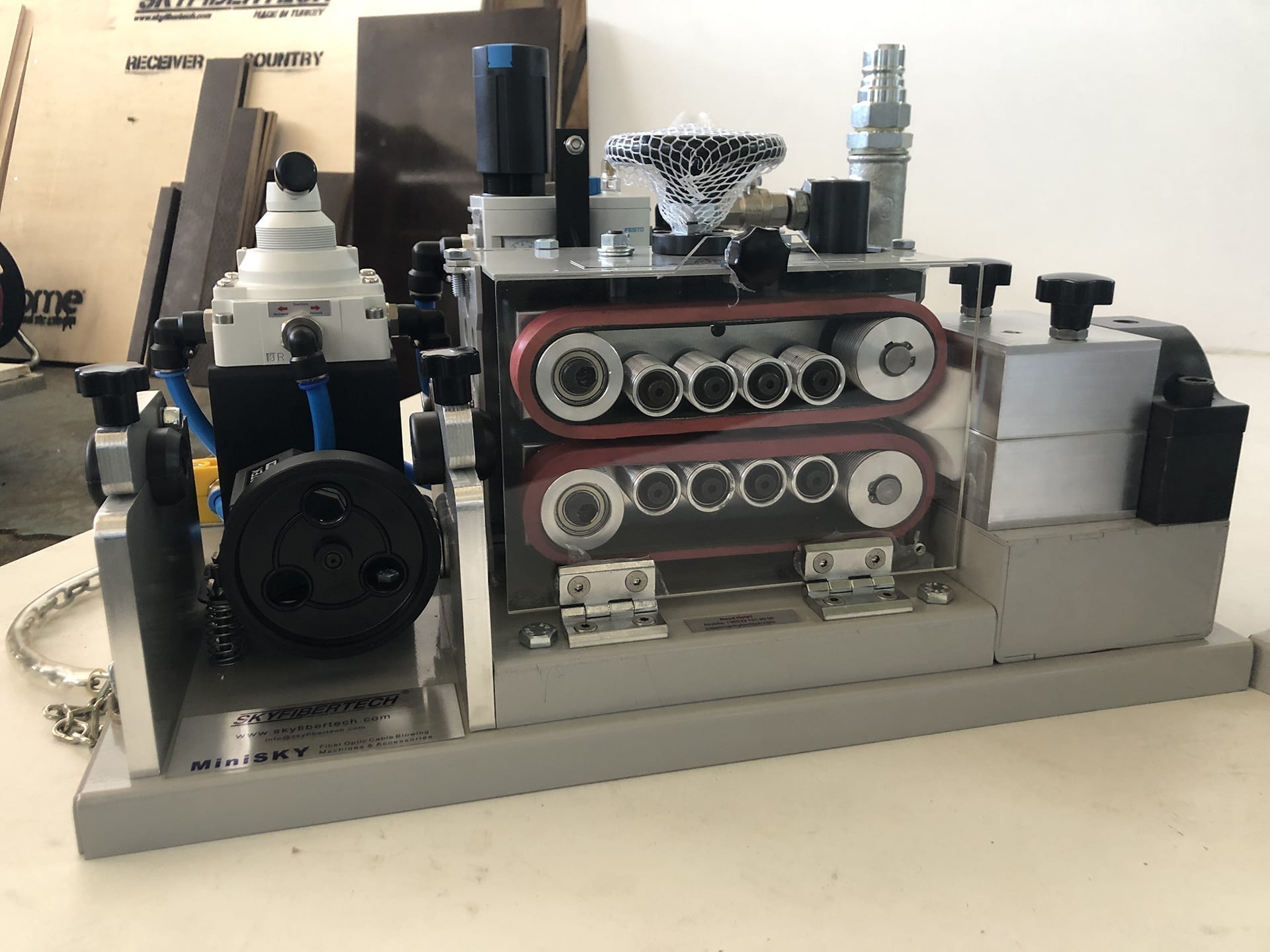

Fiber Blowing Machines

To install fiber optic cable there are many arrangement needs to be made as it is quite sensitive type of cable used for high capacity data transfer. Microduct fiber blowing machines is one of the necessary expensive machine that is being used to make the installation easier. While establishing a fiber optic connection within a perimeter this machine shows an outstanding efficiency. The level of manual laborbecomes rapidly less by using a blowing machine which works on the compressor with heavy air pressure and establish a network under the surface very cost effectively.

There are many other machines like microduct fiber blowing machines also used to push the fiber cable between the HDPE ducts which keep the cable safe from external hazards. Talking of fiber optic cable you have to be extra careful while using this machine and this special cable which works on the optical fiber signal. Basically, ina manual network installation, there are several risks and extra costs involved that is the reason the jetting machine and blowing machine comes into the picture to make the work super flexible with less human effort.

There are many features of microduct fiber blowing machines which is especially built to handle large and small network by using fiber optic cable. The operator just needs to know the controls and step by step procedure to start and stop the machine and the rest of the blowing of cable through the duct will be done by this machine and definitely in less time.